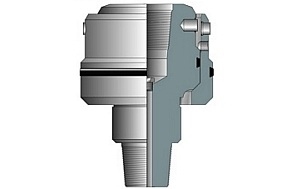

Tool to install / remove the wear bushing

It allows installing and retrieving the wear bushing. It locks inside the wear bushing with a quarter turn to the right, and unlocks with a quarter turn to the left.

_________________________________________________________________________________________________________________________________________________________________________________

Combined Tool

The HCC combined tool is connected to the drilling pipe. With the male thread facing up, it installs or retrieves the wear bushing. With the male thread facing down, it seals the head or spool housing and allows for testing the pressure of preventors. Bushings are used to adapt the basic tool to different sizes. The drill pipe can be suspended below the test plug, thus eliminating the need to trip the whole pipe out of the hole.

_________________________________________________________________________________________________________________________________________________________________________________

Wear Bushing

The wear bushing is housed in the head or in the spool and is secured by means of two tie down screws to protect it against damage or wear during drilling. It is installed or retrieved with either a simple installation tool or with the HCC combined tool.

_________________________________________________________________________________________________________________________________________________________________________________

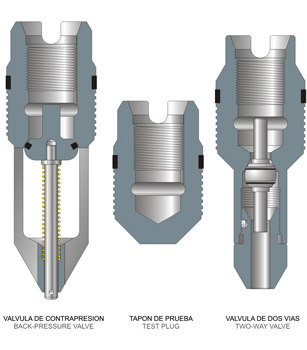

Type H back-pressure valve

The type H back-pressure valve is used to seal the tubing pressure up to 15,000 psi while the blowout preventors are removed and the Christmas tree is installed. It also allows fluid to be circulated down the tubing and prevents backflow.

If it is required to pressure-test the Christmas tree, a two-way check valve must be installed. This valve also allows the pressure to be equalized above and below the seat, in order to safely remove the tubing hanger.

_________________________________________________________________________________________________________________________________________________________________________________

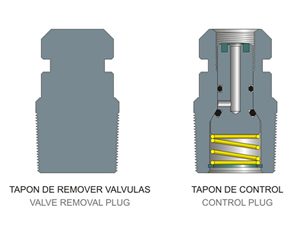

Valve removal plug and control plug

The valve removal plug allows installing and removing a valve that is under pressure up to a 15,000 psi, with the help of a lubricator.

The control plug is a check valve that allows a pressure gauge to be installed on the side outlet of a spool. Along with the control plug, a flange with a housing for the control plug shall be used.

_________________________________________________________________________________________________________________________________________________________________________________

Lubricator

The lubricator is a tool that allows installing or retrieving the type H back-pressure valve or the valve-removal plug under pressure in the well. It is installed on the tree cap by using the appropriate adapter fittings. The manual lubricator is used to handle pressures up to 10,000 psi. The hydraulic lubricator can handle pressures up to 15,000 psi, and is also used to install or remove heavy tools such as fracture sleeves. In order to maximize safety and minimize the possibility of failure, the lubricator must be operated by a highly-trained technician, and undergo regular inspection to ensure reliability.