- Details

-

Category: Uncategorised

-

Published: Tuesday, 23 January 2018 12:53

-

Written by Super User

-

Hits: 4271

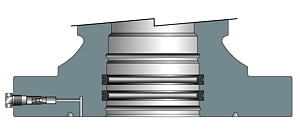

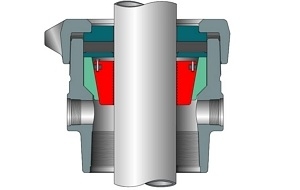

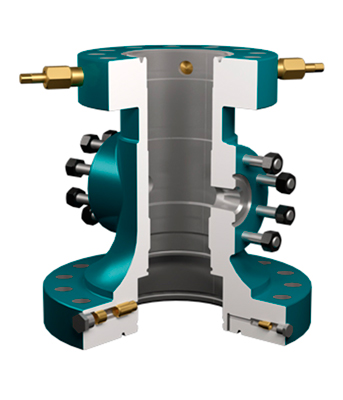

Casing Spools MC Type

The MC casing spools are standard-manufactured in order to house MC-21, MC-22 and MC-29 casing hangers. Side outlets may be either threaded or flanged. Side outlets with open flanges or studded flanges have an inner thread for a valve removal plug.

The MC casing spools are available with a bottom preparation to house type DSS, DSP or X secondary packing and the bit pilot.

Also available are MC-22P and MC-29P intermediate heads are manufactured with two tie-down screws to secure the wear bushing. These do not accept type H seal rings.

- Details

-

Category: Uncategorised

-

Published: Tuesday, 23 January 2018 12:52

-

Written by Super User

-

Hits: 5042

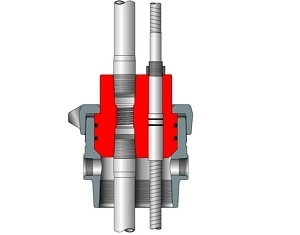

MODEL CU

They are heads intended to hang tubing. They have a cylindrical housing for the hanger. The bottom connection is threaded. They have threaded 2”LP side outlets and a closing cap tightened with hammer union to seal the annulus space. The upper thread is 8 5/8" CSG.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL CI

They are heads intended to hang casing. They have a cylindrical housing for the hanger. The bottom connection can be either threaded or ready for welding. They have threaded 2”LP side outlets and a closing cap tightened with hammer unions to seal the annulus space . The upper thread is 13-3/8" csg.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL CUP

They use the same body and cap as the CI model heads, except they have an adapter to house the slips, seal, and gland flange.

_________________________________________________________________________________________________________________________________________________________________________________

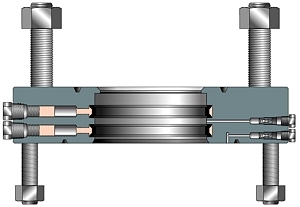

INDEPENDENT WELLHEAD ADAPTERS

Independent wellhead adapters are used to adapt a model CU casing spool over the lower head of a model CI lower casing. It can be used as contingency equipment in case of damage to the casing spool thread. It is also ideal for adapting a flanged tubing spool to a lower independent casing head, as it provides a secondary seal in the casing spool.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL CUB

They are the same as model CU wellheads, except they have a flanged bottom connection and secondary seal.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL CUBP

They are heads intended to hang tubing. They have a flanged bottom connection and a gland to pack the tubing.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL CUS

They are heads intended to hang tubing similar to model CU heads, except they add an adapter that allows a stripper to be housed. The stripper provides an annulus seal that allows safe handling of the tubing.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL CUBE

Model CUBES independent wellheads are similar to model CU wellheads, except they have a hanger that allows hanging the string of tubing, and a preparation to install an electrical connector for the power cables of the electrical submersible pump.

_________________________________________________________________________________________________________________________________________________________________________________

- Details

-

Category: Uncategorised

-

Published: Tuesday, 23 January 2018 12:52

-

Written by Super User

-

Hits: 4165

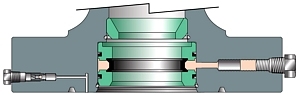

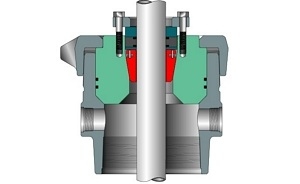

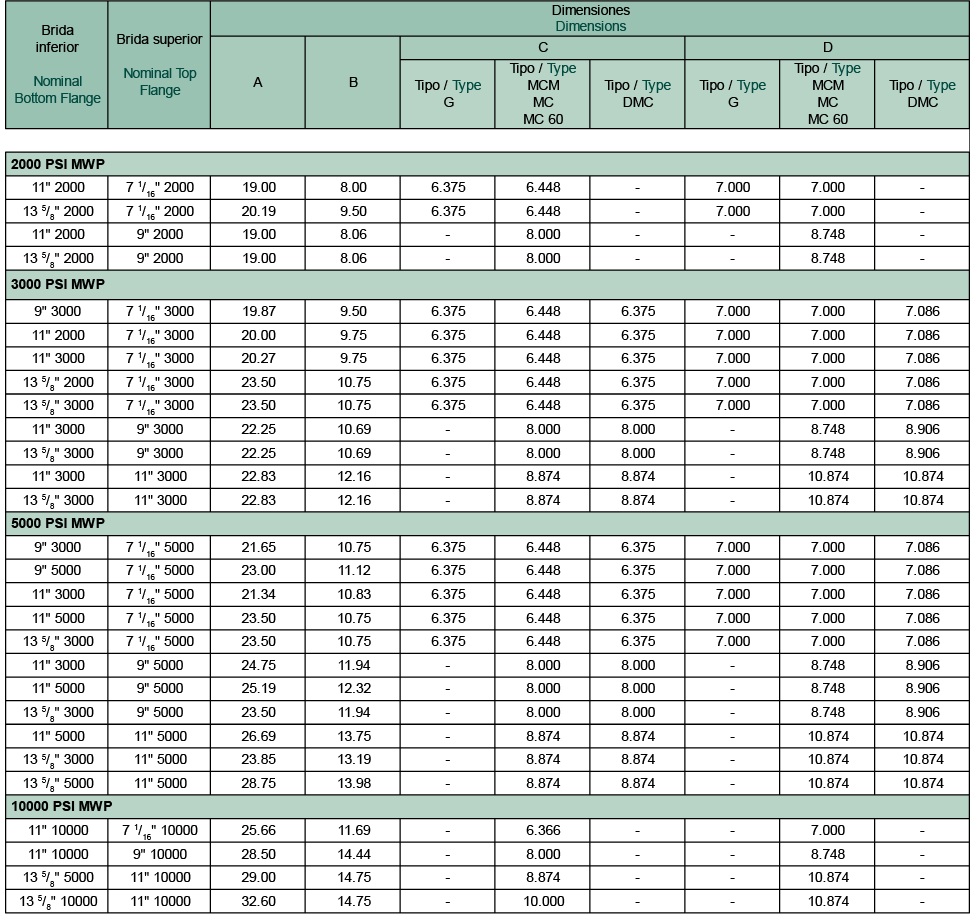

MCM Tubing Spools

MCM tubing spools are standard-manufactured in order to house MC-1W, MC-1A, MC1A-BP, MC1, MC2, and MC-29 tubing hangers. Top flanges have tie-down screws to energize the annulus seal.

Side outlets may be either threaded or flanged. Side outlets with open or studded flanges have inner threads for valve removal plugs. MCM intermediate spools are furnished with bottom preparations to house type DSS, DSP or X secondary packing and the bit pilot.

_________________________________________________________________________________________________________________________________________________________________________________

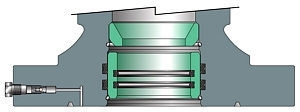

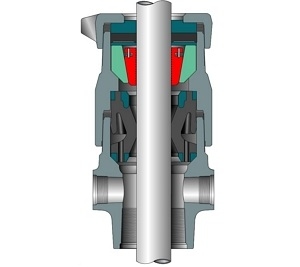

TFF-FC Tubing Spools

They are similar to the MCM tubing spools, except they include an alignment pin to guide the tubing hanger when it has an alignment groove. They allow housing the same tubing hangers as the MCM spools, and MC-BES hangers as well.

_________________________________________________________________________________________________________________________________________________________________________________

MC 60 Tubing Spools

They are identical to the TFF-FC tubing spools and they allow housing the same tubing hangers. But, in addition, they have two robust alignment pins to guide and support the tubing hangers for MC-60 dual completion.

_________________________________________________________________________________________________________________________________________________________________________________