- Details

-

Category: Uncategorised

-

Published: Tuesday, 23 January 2018 13:00

-

Written by Super User

-

Hits: 6760

Web Nordeste offers a full line of valves for use in oil and gas wells in sizes ranging from 2-1/16" to 9", in pressures from 2,000 to 15,000 PSI, and all kinds of materials according to API 6A, as well as other materials for special services.

_________________________________________________________________________________________________________________________________________________________________________________

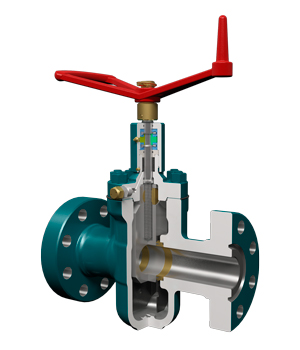

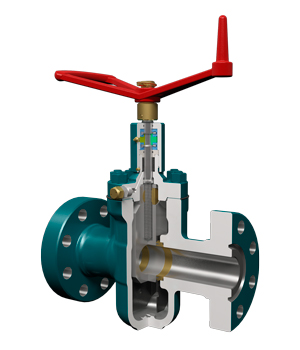

MODEL T2 API 6A 2,000 PSI GATE VALVE

Model T2 valves are used for various well or plant services requiring bi-directional valves.

Model T2 valves feature a slab gate and floating seats. The pressure energizes the seats against the gate, achieving a tight seal upstream as well as downstream. When the valve is closed, the handwheel must be backed off ¼ turn.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL T5 API 6A 3/5,000 PSI GATE VALVE

Model T5 API 6A gate valves has been developed as on-off valves to cover a wide range of applications in oil and gas services up to a maximum operating pressure of 5,000 PSI.

They are manufactured with flanged and threaded ends in sizes from 2-1/16" up to 7-1/16", meeting the requirements of materials per API 6A classes AA to FF, and in PSL 1 to 3G specification levels, and performance requirement level PR2.

FEATURES:

- Metal to Metal seal: Metal-metal seal between gate and seat.

- Bidirectional sealing: The gate and the seats seal in both directions. The gate and the seats can be reversed for increased life of the valve.

- Stem packing: The non-elastomeric stem packing is unaffected by H2S, CO2, amines or any other chemical substances commonly found in oil or gas wells. Its design favors low operating torque under any service condition.

- Easy operation: The valve opens and closes without needing excessive torque. After the necessary number of turns required for closing the valve, the handwheel must be backed off ¼ turn.

- Body without penetrations: The valve body has no penetrations. For safety, the grease fitting is located on the bonnet, downstream from the backseat.

- Stem shear pin: The stem is protected against excessive torque by a stem shear pin. The pin can be readily replaced without disassembling the valve bonnet.

- Replaceable seats: The floating seats can be easily replaced in the field.

- Valves with actuator: Model T5 API 6A gate valves can be converted into safety valves by adding pneumatic or hydraulic actuators.

_________________________________________________________________________________________________________________________________________________________________________________

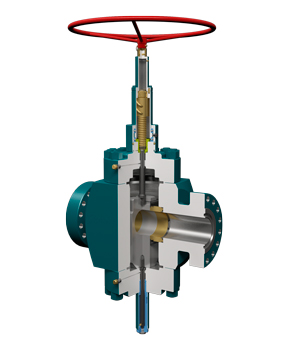

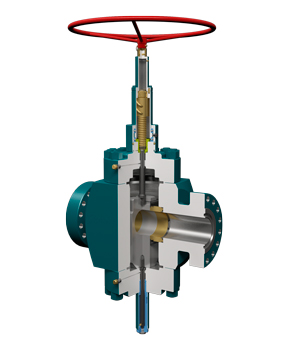

MODEL T10 API 6A 10,000 PSI GATE VALVE

Model T10 API 6A gate valves are shutoff valves developed to meet a wide range of applications in oil and gas services up to 10,000 PSI operating pressure. They are manufactured with flanged ends from 2-1/16" up to 7-1/16", meeting the requirements of materials per API 6A classes AA to FF, and in PSL 2 to 4 specification levels. Their simple and robust design provides a long lasting and reliable service with minimal maintenance.

FEATURES:

- Metal-to-Metal seal: Metal-metal seal between gate and seat and between seat and body.

- Bidirectional sealing: The gate and the seats seal in both directions. The gate and the seats can be reversed for increased life of the valve.

- Back-seating: The stem is designed to make a metal-metal back-seat in the bonnet, which allows the stem packing to be replaced while the valve is in service.

- Stem packing: The non-elastomeric stem packing is unaffected by H2S, CO2, amines or any other chemical substances commonly found in oil or gas wells. Its design favors low operating torque under any service condition.

- Easy operation: The valve opens and closes without needing excessive torque. After the necessary number of turns required for closing the valve, the handwheel must be backed off ¼ turn. The valve is then fully closed.

- Body without penetrations: The valve body has no penetrations. For safety, the grease fitting is located on the bonnet, downstream from the backseat.

- Stem shear pin: The stem is protected against over-torquing by a stem shear pin. The pin can readily be replaced without disassembling the bonnet.

- Replaceable seats: A haste está protegido contra a aplicação de excesso de torque por um pino de cisalhamento. Este pino pode ser substituído facilmente sem desmontagem do castelo.

- Sede substituível: The floating seats can be readily replaced in the field.

- Valves with actuator: Model T10 API 6A gate valves can be converted into safety valves by adding pneumatic or hydraulic actuators.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL T15 API 6A 15,000 PSI GATE VALVE

Model T15 API 6A gate valves are shutoff valves developed to meet a wide range of applications in oil and gas services up to 15,000 PSI operating pressure. They are manufactured with flanged ends from 2-1/16" up to 7-1/16", meeting all the requirements of materials per API 6A class AA through FF, and in specification levels PSL 2 through 4.

Their simple and robust design provides a long-lasting and reliable service with minimal maintenance.

FEATURES:

- Metal to Metal seal: Metal-Metal seal between gate and seat and between seat and body.

- Bidirectional sealing: The gate and the seats seal in both directions.

- Back seat: Both stems have a metal-metal back seat, which allows for the packing to be replaced while the valve is in service.

- Stem packing: The non-elastomeric steam packing is unaffected by H2S, CO2, amines or any other chemical substances normally found in oil or gas wells. Its design favors low operating torque under any service condition.

- Easy operation: The valve opens and closes without needing excessive torque. The screw-and-nut actuating system with recirculating balls is for high performance, which allows the valve to be operated directly without the need of a gear box. This system minimizes the number of handwheel turns for operation. After the necessary number of turns required for closing the valve, the handwheel must be backed off ¼ turn.

- Body without penetrations: The valve body has no penetrations. For safety, the grease fitting is located on the bonnet, downstream from the backseat.

- Stem shear pin: The stem is protected against over-torquing by the stem shear pin. The pin can be readily replaced without disassembling the bonnet.

- Replaceable seats: The floating seats can be easily replaced in the field.

- Seat protector: A protecting ring between seat and body protects the lip of the metal-metal seal.

- Valves with actuator: The API 6A model T15 gate valves can be converted into actuated valves by adding pneumatic or hydraulic actuators.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL T10BR 10,000 PSI GATE VALVE

The model T10BR API 6A gate valve has a balanced stem and recirculating balls. It has been developed to manually operate large-diameter and high-pressure valves. It is used to serve as a on-off valve in oil and gas services up to 10,000 PSI.

. It is manufactured in sizes from 4-1/16" to 9". It is suitable for use in production trees, conduction systems and fracture trees.

FEATURES:

- Metal to Metal seal: Metal-Metal seal between gate and seat and between seat and body.

- Bidirectional sealing: The gate and the seats seal in both directions.

- Back seat: Both stems have a metal-metal back seat, which allows for the packing to be replaced while the valve is in service.

- Stem packing: The non-elastomeric steam packing is unaffected by H2S, CO2, amines or any other chemical substances normally found in oil or gas wells. Its design favors low operating torque under any service condition.

- Easy operation: The valve opens and closes without needing excessive torque. The screw-and-nut actuating system with recirculating balls is for high performance, which allows the valve to be operated directly without the need of a gear box. This system minimizes the number of handwheel turns for operation. After the necessary number of turns required for closing the valve, the handwheel must be backed off ¼ turn.

- Body without penetrations: The valve body has no penetrations. For safety, the grease fitting is located on the bonnet, downstream from the backseat.

- Stem shear pin: The stem is protected against over-torquing by the stem shear pin. The pin can be readily replaced without disassembling the bonnet.

- Replaceable seats: The floating seats can be easily replaced in the field.

- Seat protector: A protecting ring between seat and body protects the lip of the metal-metal seal.

- Valves with actuator: The API 6A model T10BR gate valves can be converted into actuated valves by adding pneumatic or hydraulic actuators.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL T15BR 15,000 PSI GATE VALVE

The API 6A model T15BR gate valve features a balanced stem and recirculating balls. It has been developed to manually operate large-diameter and high-pressure valves.

It is used to serve as a on-off valve in oil and gas services up to 15,000 PSI. It is manufactured in sizes from 4-1/16" to 7-1/16". It is suitable for use in production trees, conduction systems and fracture trees.

FEATURES:

- Metal to Metal seal: Metal-Metal seal between gate and seat and between seat and body.

- Bidirectional sealing: The gate and the seats seal in both directions.

- Back seat: Both stems have a metal-metal back seat, which allows for the packing to be replaced while the valve is in service.

- Stem packing: The non-elastomeric steam packing is unaffected by H2S, CO2, amines or any other chemical substances normally found in oil or gas wells. Its design favors low operating torque under any service condition.

- Easy operation: The valve opens and closes without needing excessive torque. The screw-and-nut actuating system with recirculating balls is for high performance, which allows the valve to be operated directly without the need of a gear box. This system minimizes the number of handwheel turns for operation. After the necessary number of turns required for closing the valve, the handwheel must be backed off ¼ turn.

- Body without penetrations: The valve body has no penetrations. For safety, the grease fitting is located on the bonnet, downstream from the backseat.

- Stem shear pin: The stem is protected against over-torquing by the stem shear pin. The pin can be readily replaced without disassembling the bonnet.

- Replaceable seats: The floating seats can be easily replaced in the field.

- Seat protector: A protecting ring between seat and body protects the lip of the metal-metal seal.

- Valves with actuator: The API 6A model T15BR gate valves can be converted into actuated valves by adding pneumatic or hydraulic actuators.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL THT API 6A HIGH-TEMPERATURE GATE VALVE

The Model THT API 6A gate valve for steam injection features:

- Operating pressures up to 3,000 PSI and temperatures up to 350ºC (650ºF).

- Metal-metal seal between body and bonnet.

- Unique design of metal-metal seal between body and seats.

- Grafoil stem packing, externally energizable.

- Grease fitting downstream from stem backseat.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL M3 API 6A 3,000 PSI BALL VALVE

Model M3 ball valve has been designed to cover a wide range of applications as a shutoff valve for oil, gas, and water service

Available in sizes from 2-1/16” to 4-1/16”, operating pressures up to 3,000 PSI with flanged, threaded or welding ends.

FEATURES:

- Through-conduit: The internal passage of the valve is full bore, without flow restrictions. This feature reduces turbulence and headloss. It is possible to pass through the valve with any tool that can pass through the internal diameter of the pipe.

- Trunnion mounted: The one piece ball-and-stem construction of the M3 ball valve is the basis of its compact and robust design. This also provides greater rigidity and alignment, reducing the wear of the bearings and the operating torque as well.

- Low operating torque: The load produced by the pressure is borne by two self-lubricated low-friction bearings that are isolated from the flow and the environment.

- Internal stops: The dual-action internal stops provide high precision at the end of the stroke during opening and closing. In the open position, this prevents exposure of the seats to flow erosion. A neoprene guard prevents the entry of particles into the stem.

- Actuators: The M3 ball valves can be supplied with electrical or pneumatic actuators for remote operation.

_________________________________________________________________________________________________________________________________________________________________________________

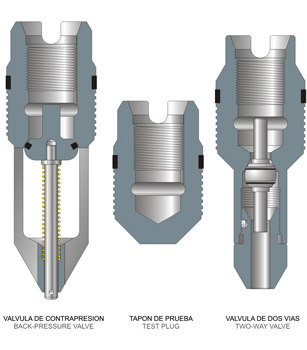

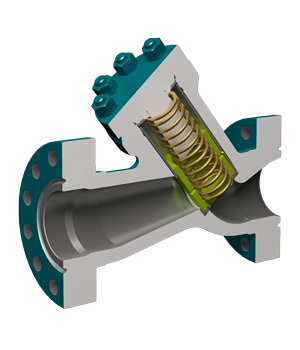

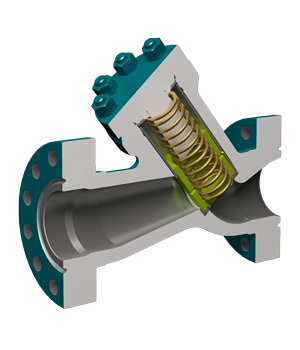

MODEL FM API 6A 3/5,000 PSI CHECK VALVE

FEATURES:

- Enhanced-flow check valves can be used in all cases where a smooth operation and the absence of vibration and shock are important.

- The internal design of the body and the angle piston allow for a straight-through flow, thus reducing the pressure drop by 20-30%.

- The internal contour minimizes turbulence and adds to the life of internal parts by eliminating vibration, which is the main cause of wear.

- The angle piston allows installation in any position along horizontal or vertical lines.

- Excellent guidance of the piston, which ensures fast and safe closing.

- In-line replaceable seats and elastomeric seals provide an effective shutoff at high and low pressures.

- Check valves are available in two models in a wide variety of materials according to the service, the FM model up to 200°C, and the FMS model up to 343°C.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL HDA SURFACE SAFETY FRAC VALVE (SSFV)

Web Nordeste manufactures valves for use in well fracturing in 3-1/16" to 7-1/16" diameters, and 10,000 PSI and 15,000 PSI pressures. Frac valves have appropriate features of design and materials for performing under these harsh service conditions. They are furnished with manual handwheel command or hydraulic actuator.

The manually controlled valves of sizes 4-1/16" and larger have a balanced stem and an actuating system mounted on recirculating balls. This feature allows the valve to be operated with a reduced number of turns and also faster, thus facilitating the operation and reducing damage to the closing components. They are also manufactured in groups of two or three valves that may include studded side outlets.

Model T-10 HDA & T-15 HDA API 6A Gate Valves are frac valves with a double acting hydraulic actuator. The double acting piston Hydraulic actuator allows the valve to be controled fast and remotely by means of a compact control panel connected at distance.

In case of not having an hydraulic pressure source, the valve has a manual override system handwheel with recirculating balls in order to open or close the valve with no excessive torque needed.

_________________________________________________________________________________________________________________________________________________________________________________

MODEL H9-300 WLC SSV VALVE

Model S10 API 6A gate valve with model H9-300 WLChydraulic actuator is mainly used in wireline operations. It works as a conventional actuator, it closes automatically at pressure control lost and will open automatically when control pressure is restaured under normal production and becomes the main surface safety device during wireline operations to ensure wireline cutting and well flow sealing in case of emergency.

This is possible because two power springs located in H9-300 WLC actuator which aplies much strenght to cut the wire.

_________________________________________________________________________________________________________________________________________________________________________________